Top > Products & Services > Nafitec® Sieve Mesh > Nafitec® Sieve Mesh Features

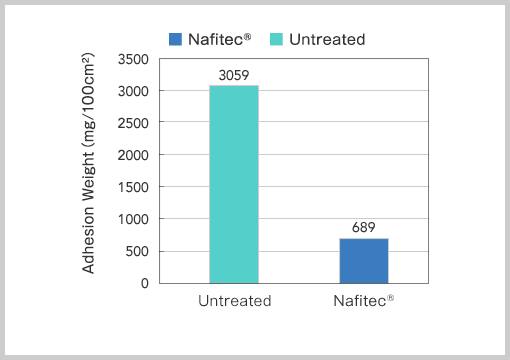

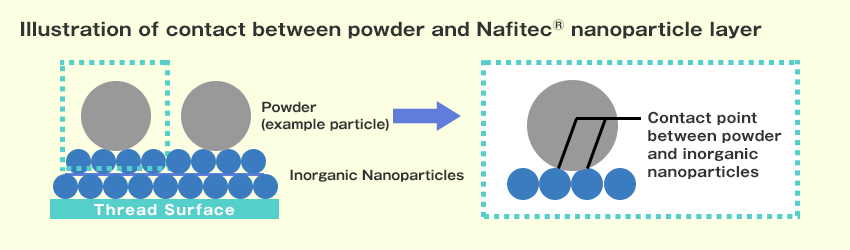

Nanoparticles are much smaller than the powder particles. So, when the powder meets the mesh, actual contact between the powder particles and the nanoparticle-covered surface of Nafitec® Sieve Mesh is kept to an absolute minimum. This prevents the powder from sticking to the Nafitec® Sieve Mesh, minimizing sieve blinding and enabling excellent powder throughput.

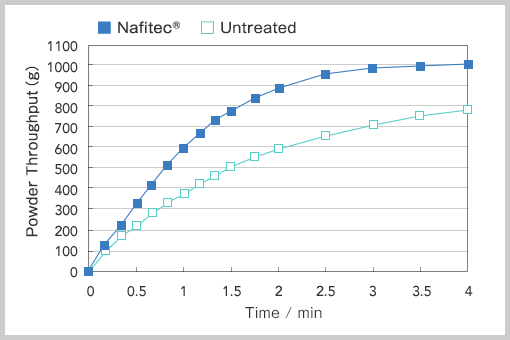

- Metal Powder

- Polymer Powder

- Ceramic Powder

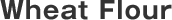

- Other

- Metal Powder

- Polymer Powder

- Ceramic Powder

- Other

-

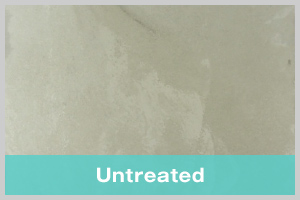

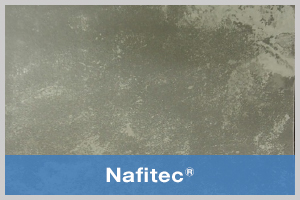

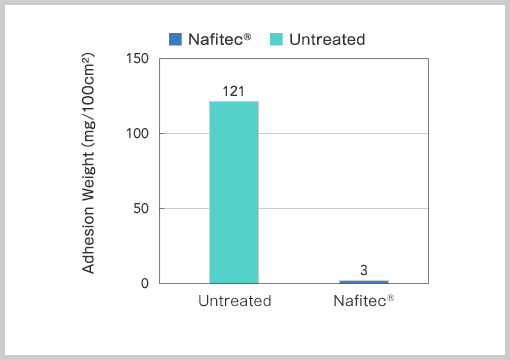

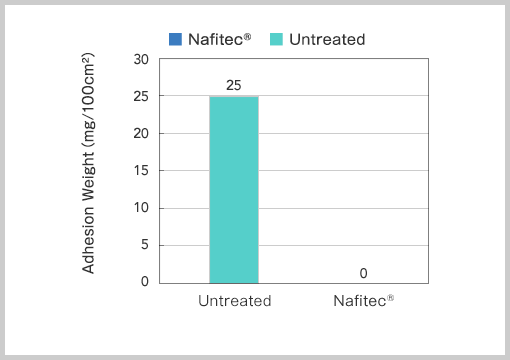

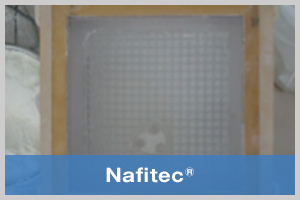

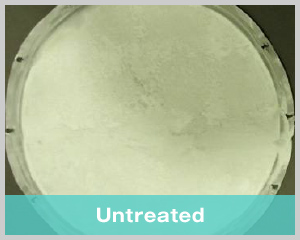

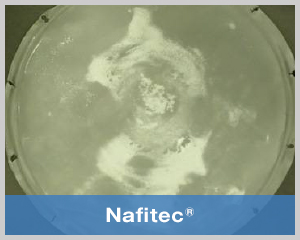

■Vibration Sifter Test

Test sifter:φ300mm vibration sifter without de-blinding balls

Test Powder:Silver powder (Ag) , D50:3 microns

Mesh Type:Stainless steel wire mesh 500 mesh (/inch), mesh opening 25 microns

-

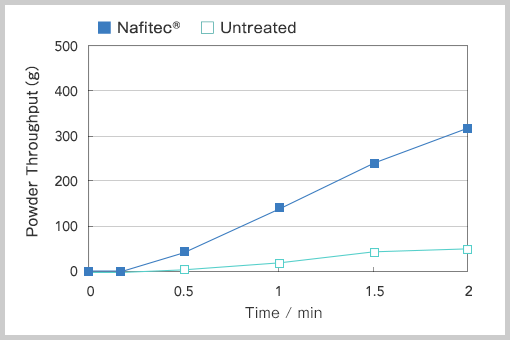

■Vibration Sifter Test

Test sieve:φ300mm vibration sifter without de-blinding balls

Test Powder:Non-magnetic toner (commercial grade) , D50:9 microns

Mesh Type:Polyester 230 mesh (/inch), mesh opening 65 microns

-

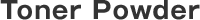

■Vibration Sifter Test

Test sieve:φ300mm vibration sifter without de-blinding balls

Test Powder:Silicon dioxide, D50:25 microns

Mesh:Nylon 230 mesh (/inch), mesh opening 67 microns

-

■Vibration Sifter Test

Test sieve:250mm x 250mm sifter

Test Powder:Wheat flour

Mesh Type:Nylon mesh, mesh opening 200 microns

Click the particle type tab to see comparison data between untreated sieve mesh and Nafitec® Sieve Mesh

To play the video, turn on Targeting Cookies in Cookie Settings and save.Then, please reload the page by clicking the reload button on your browser or pressing F5 key on your keyboard.

Compatible Powders

| Category | Powder Types | Advantages |

|---|---|---|

| Metal Powder | Silver, copper, nickel, metallic silicon alloy, iron powder | • Improves final sieving efficiency (speed) • Improves sieving efficiency (yield) • Reduces sieve blinding and frequency of screen replacement (Longer service life) |

| Polymer Powder | Toner, powdered paint, polyethylene (PE) powder, polytetrafluoroethylene (PTFE) powder, cellulose | • Improves sieving efficiency (speed) • Reduces maintenance frequency |

| Ceramic Powder | Silicon dioxide, aluminum oxide, magnesium oxide, magnesium hydroxide, magnesium carbonate, metal oxide (for battery material) | • Improves sieving efficiency (speed) |

| Other | Wheat flour, carbon, titanate, barium titanate, calcium carbonate, talc | • Improves sieving efficiency (speed) • Reduces maintenance frequency |

Note: We are currently researching the effectiveness of Nafitec® Sieve Mesh with a variety of additional powder types

Nafitec® Sieve Mesh comes in a range of specifications to match each powder type. We can provide a standard Nafitec® Sieve Mesh specification ideal for your particular powder needs, or a custom order specification adapted to your requirements. Please consult us today regarding any further questions or inquiries.

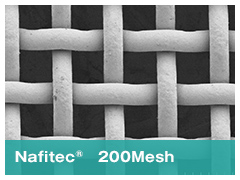

- Materials Compatible with Nafitec® Treatment

Stainless steel wire mesh, nylon mesh, polyester mesh

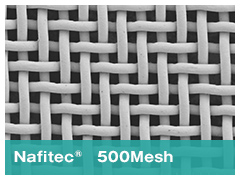

Mesh Counts

A wide range from coarse meshes to fine meshes