Technology in the Spotlight

Precision weaving techniques

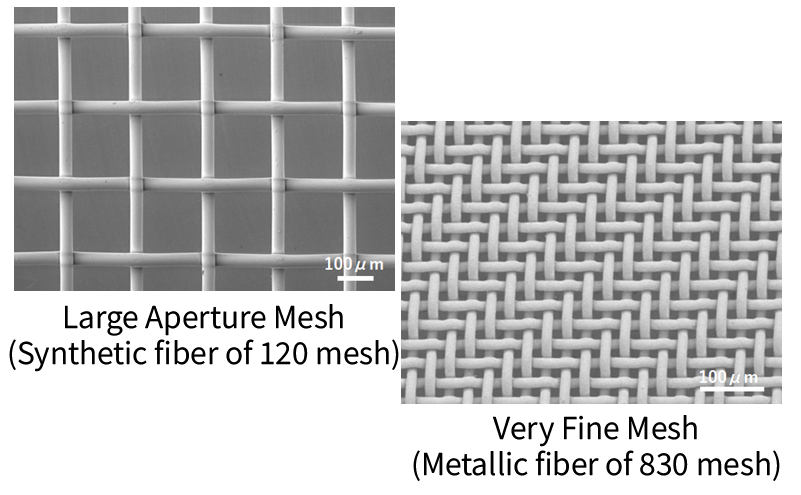

Mesh cloth woven by NBC Meshtec

Exquisite quality from coarse to fine mesh

We manufacture products from 5 mesh at the coarsest to 830 mesh at the finest*.

The process of drawing warp threads for mesh cloth, called warping, involves a sophisticated technique of passing dozens of threads through a width of less than 1 mm.

NBC Meshtec's technology, know-how, and ingenuity produce accurate and uniform mesh cloth at any density.

- 5 mesh: Mesh cloth with 5 threads per inch (2.54 cm)

830 mesh: Mesh cloth with 830 threads per inch (2.54 cm)

Both synthetic and metallic fibers are available.

We are one of the few mesh cloth manufacturers in the world that handle both synthetic and metallic fibers.

Synthetic and metallic fibers involve similar basic production processes for mesh cloth, but require different production equipment and technical elements.

We have amassed a high level of technology and know-how by handling requests for a wide range of materials.

Unique design and production technology

Our R&D department, with its scientific and technical perspective, and our manufacturing department, with its master craftsmanship and mechanical knowledge and experience, have established unique design and production technologies to reliably meet the high demands of our customers.

- Proposal of woven fabric design based on weaving know-how ⇒ Production of mesh cloth that meets performance requirements

- Enhanced responsiveness through automation of processes and customization of equipment⇒ Improved weaving accuracy and quality

- Functionality added to mesh cloth through processing technology⇒ Multi-functional mesh cloth

Providing mesh cloth suitable for your application

In developing and providing mesh cloth, it is important that proper performance is ultimately achieved for the customer's application.

We design, develop, and produce our products by making full use of our weaving and processing technologies, as well as by conducting evaluations based on the assumption of actual use environments.

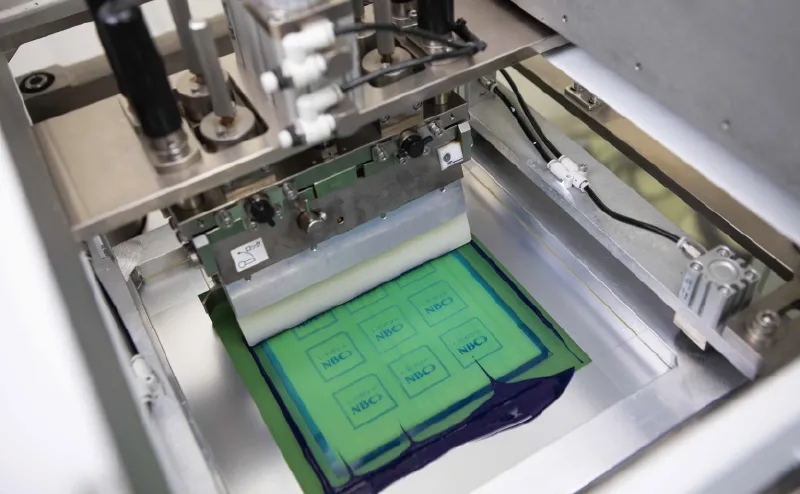

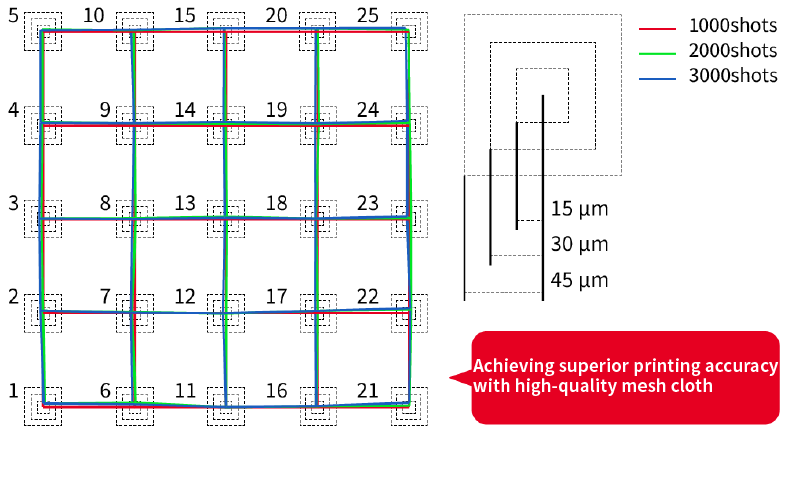

For example, in screen printing applications, the results of printing tests are incorporated into the design to further improve factors that affect printing accuracy, such as mesh cloth wire diameter, precision of openings (OP), suitability of tenacity and elongation, and weave structure.

Our mesh cloth, produced through a combination of weaving, processing, and evaluation technologies, demonstrates its performance and contributes to a variety of industrial fields.

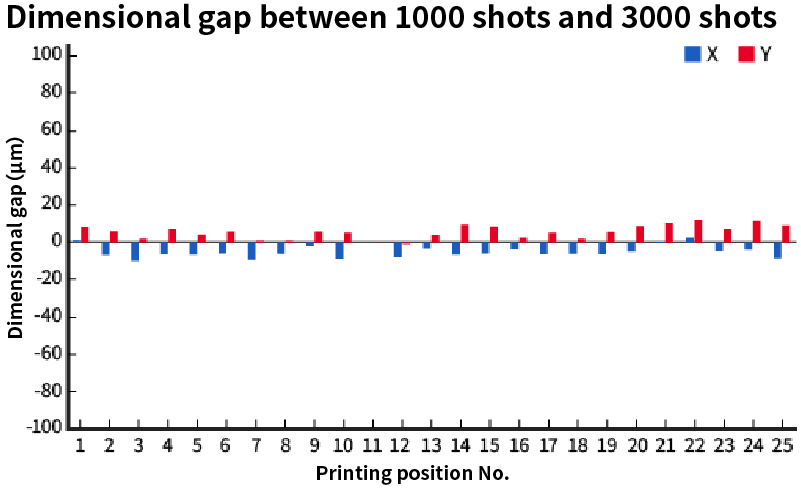

[Platemaking conditions]

- Mesh cloth used: W40 430-13

- Frame size: 320 mm × 320 mm

- Pattern area: 120 mm × 120 mm

[Printing conditions]

- Clearance: 1.3 mm

- Squeegee speed: 150 mm/sec

- Printing pressure: 50 kPa

Printing dimensional accuracy in screen printing Evaluation example

Recommendations

Did you find what you were looking for?

Please feel free to contact us if you have any questions about NBC Meshtec's technologies.