R&D Organization

Mesh Technology Laboratory

What is the Mesh Technology Laboratory?

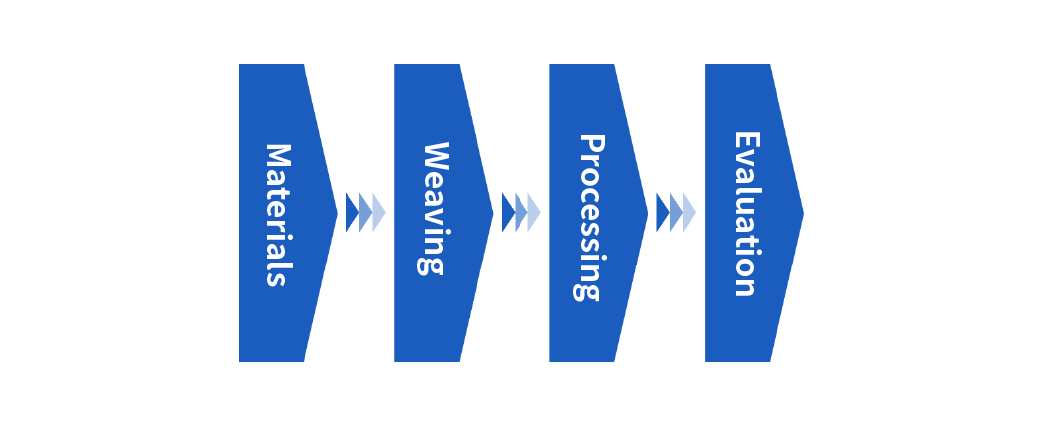

The Mesh Technology Laboratory is a comprehensive R&D organization responsible for all technologies related to mesh cloth, including materials, weaving, processing, and evaluation.

We are constantly striving to develop our technologies so that we can continue to grow as a company.

Material and fiber technologies

We handle a variety of materials from synthetic to metallic fibers.

We search, select, analyze, and develop new materials, leading to the development of unique and highly functional products.

Examples of materials we handle

| Classification | Materials |

|---|---|

| General purpose plastics | Polyester (PET), nylon (Ny6, Ny66), polypropylene (PP), polyethylene (PE) |

| Super engineering plastics | PEEK, PPS, liquid crystal polymer (LCP) |

| Metal | Stainless steel (SUS), tungsten (W), nickel (Ni), copper (Cu) |

| Low environmental impact materials | Biomass plastics, recycled materials |

Weaving technology

We create new types of never-before-seen mesh cloth through the development of weaving technology.

By using different types of looms, various types of mesh cloth can be woven, and quality and productivity can be improved.

Types of looms (examples)

[Shuttle loom]

These looms use a shuttle to insert the weft yarn and have been in use for a very long time.

In addition to being applicable to a wide range of materials, the mesh is woven while folding the weft yarn, resulting in woven fabric with no frays on the selvage ends, as well as tubular woven fabric.

[Rapier loom]

Weaving is performed by inserting the weft yarn using a rapier.

It is highly versatile and can be used to weave mesh cloth of a variety of structures.

[Gripper loom (projectile loom)]

Weaving is performed by inserting the weft yarn using a small metal part called a gripper shuttle.

The mesh can be woven to be wide, making this loom suitable for mass production.

[Water jet loom/Air jet loom]

Mesh cloth is woven by carrying the weft yarn using water or air currents.

This loom is characterized by its high productivity.

We can perform trial weaving (prototyping) and simulations of mesh cloth according to customer requirements.

We offer trial weaving (prototyping) services in accordance with customer requests by utilizing the design and weaving technologies we have cultivated over many years in a variety of fields.

We can also produce mesh cloth with specifications that are not included in our product lineup, so please contact us.

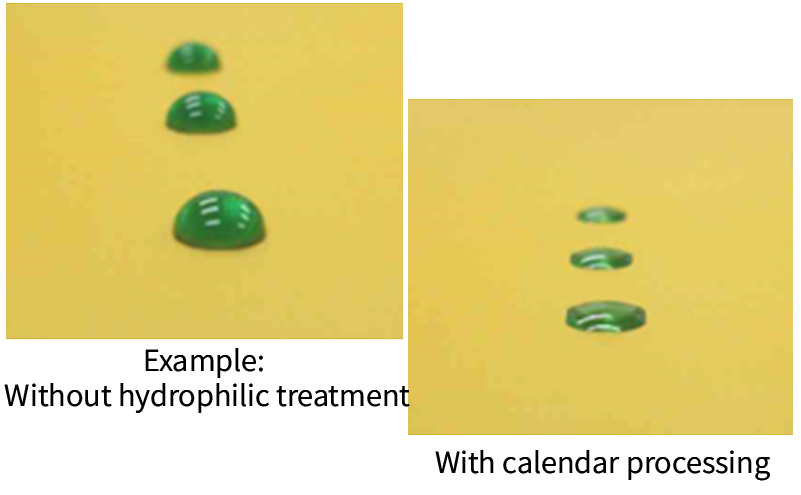

Processing technologies

We control the properties of mesh cloth through various processes to add high functionality and value.

In the establishment of processes, we are involved in everything from lab-scale testing to the configuration of processing conditions of the actual equipment.

Physical and thermal properties

- Heat setting

Dyeing

- Designability

- Aesthetics

- Prevention of halation

Added functionality

- Texture improvement (resin treatment)

- Antistatic

- Dust prevention and adhesion control

- Hydrophilic (corona treatment)

- Water and oil repellency

Shape processing, others

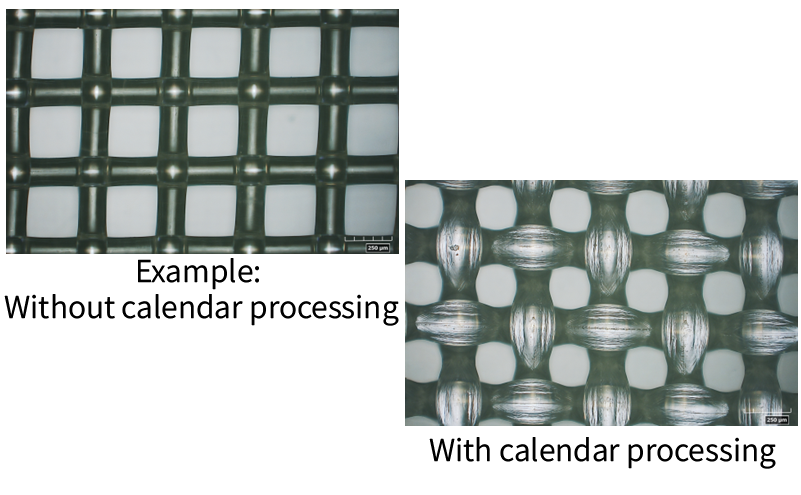

- Calendering

- Pleating

- Slitting

- Sewing

Evaluation technologies

In addition to evaluating the basic physical properties of mesh cloth, we also evaluate various properties for different applications.

Basic physical properties

- Tensile elongation

- Tear strength

- Burst strength

- Texture

- Appearance

Mesh cloth material properties

- Air permeability

- Particle size

- Thermal property

- Polymer crystalline

- Wettability/water repellency

- Surface irregularities

- Surface resistivity

- Spectral properties

- Weather resistance

Application-specific properties

- Screen printing property

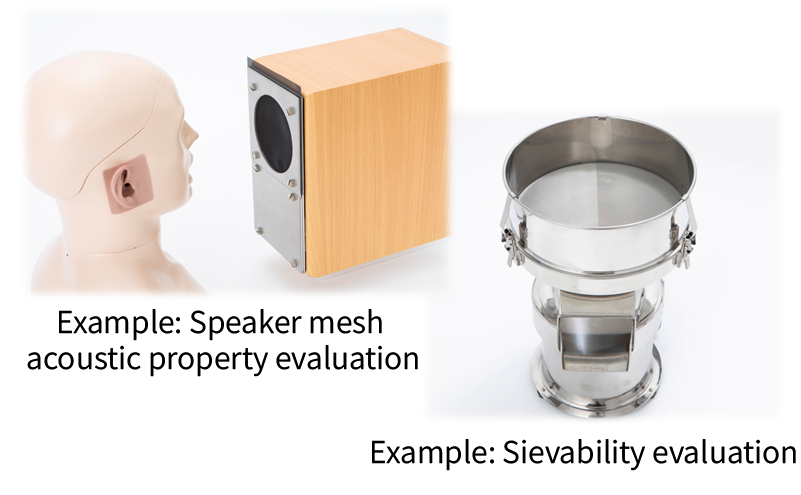

- Sievability

- Acoustic properties

- Electromagnetic shielding

Recommendations

Did you find what you were looking for?

Please feel free to contact us if you have any questions about NBC Meshtec's technologies.