R&D Organization

Production Technology Development Center

Initiatives of the Production Technology Development Center

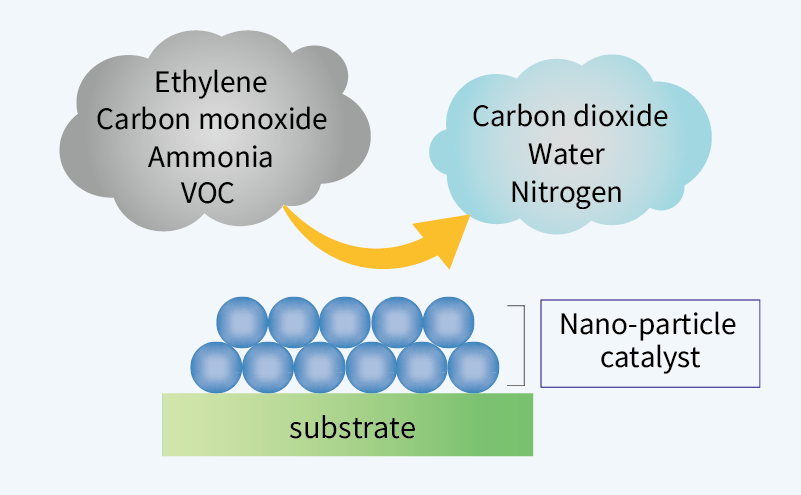

We evolve our mesh application technology by accurately identifying market needs while giving consideration to human safety, equipment safety, product safety, and environmental measures.

Engineering Organization

Unique production system that achieves both quality and cost

In order to establish a production system that achieves both quality and cost and responds flexibly to fluctuating demand, we are striving to develop production technology intended to establish harmony between man and machine by bringing together all knowledge and technologies, including IE and safety engineering, as well as electricity, machinery, and electronics.

In the production process, we, ahead of others, introduced industrial robots and cutting edge equipment, which freed workers from monotonous repetitive operations and harsh working environments, thereby realizing improved quality, cost reduction, and higher productivity. In promoting this policy, we stick to the philosophy "Build in quality with the manufacturing process,” which has been our basic policy since our establishment.

In addition, we are proactively committed to establishing a unique production system that enables efficient production with as little manpower as possible by centrally controlling process control and quality control information by computer.

-

Manufacturing machine design

-

Equipment assembly

-

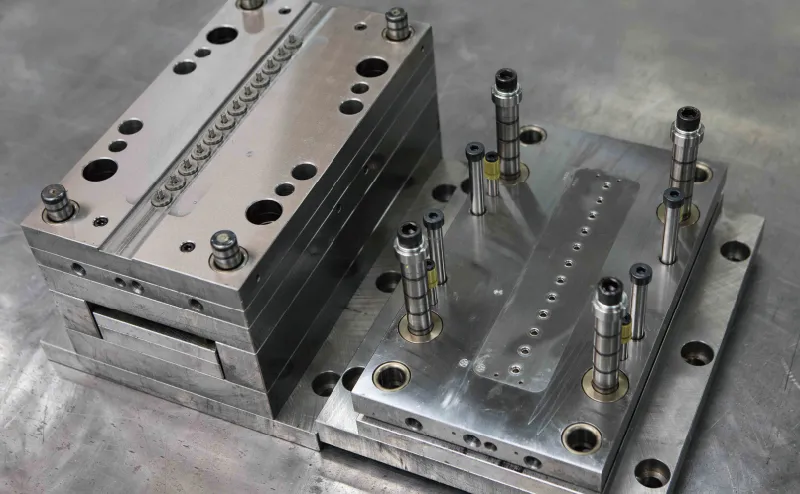

Mold design and manufacturing

Support for the creation and development of new products

(1) Discontinuation of sewing and organic solvents

Discontinuation of machine sewing

Ultrasonic (high frequency) welding, laser welding

- Differentiation of fabric ducts for air conditioning:

Proposal for use of long fibers for clean room, discontinuation of sewing, and PP meshes for teabags

Bonding using adhesives

Utilization of hot melt

- Application to screen stretchers and sieve stretchers (under consideration)

(2) Applications of weaving technology

Precision filter cloth, new materials

High mesh airflow control

- Proposal for meshes for mobile phones and headphones

- Proposal for use for sludge treatment, etc.

(3) Micropore processing

Laser processing technology survey

Laser micropore processing in ultraviolet regions

- Laser porous plate evaluation (application under consideration)

(4) Quality improvement: Automatic mesh inspection device

Selection of appropriate image processing logic for mesh inspection

(5) Quality improvement: Improvement of factory cleanliness

Securing of cleanliness at a food factory level

(6) Energy saving and low cost: Use of spring water and well water on premises

Improvement of heat pump efficiency

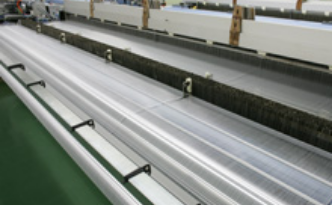

Mesh cloth production process

The process of manufacturing mesh cloth is introduced step by step.

View the mesh cloth production process

Chemical production process

Products are produced utilizing an integrated system, from design to molding, product inspection, and shipment.

View the chemical production process

Recommendations

Did you find what you were looking for?

Please feel free to contact us if you have any questions about NBC Meshtec's technologies.